The mil series - the worlds most durable ?

fundamental design concept

Commercial divers are common to have the habit to be not too careful. Ofcourse, this doesn't apply to them all - but still to some. Cold and harsh environments are just another day at the office, both for the diver but also for his gear. So what we wanted to do was to design a regulator so resistant to wear and tear as possible. The result was the MIL series.

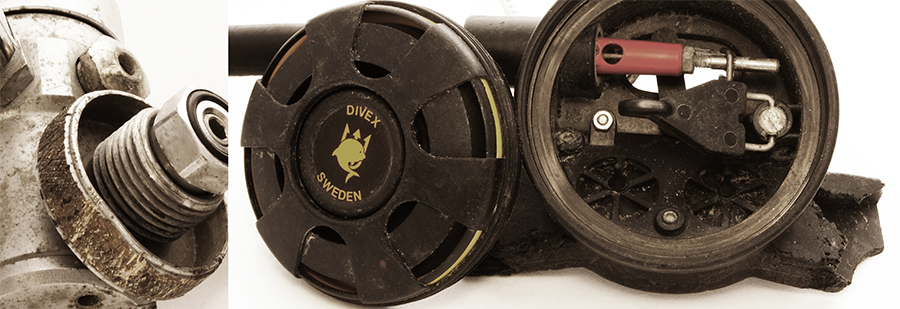

The picture shows our previous model, the Divex 950. This regulator had been in commercial use for more than 10 years without maintenance. When we did the pretest of its performance before a full service - it was still working flawlessly without any leakage or malfunctions.

first stage

The first stage itself weighs almost 1 kg. The massive body of the first stage makes it resistant to rough handling. The brass walls that protect the inner mechanisms are 12mm (960) and 15mm (970) thick and as for the top cover, we've never experienced a broken one based on thousands of regulator services.

The top cover is also designed for fieldworthiness - not only for the look. The milled holes are intentionally made in a specific size, they are big enough to prevent ice from forming and mud from sticking. But they are also crucial for the regulator to automatically adjust to the current ambient pressure during diving.

Hoses

The hoses of the MIL regulators are made from a reinforced rubber hose, wrapped in a protective sleeve for a greater wear resistance. It has a burst pressure of 80 bar, far beyond the intermediate pressure of 5 bar. The hose has a tensile strength of 90 kg and even more for the hose nipple mountings.

second stage

In general, the primary unit of regulators that freezes and causes it to free flow is the second stage. This is caused by ice formations inside the second stage, and ice prevents parts from moving properly in terms of opening and closing. In the MIL Series second stage the spaces between moving parts and the housing are large enough to prevent ice from forming, even under the most extreme conditions. The low intermediate pressure of 5 bar keeps a reduced air speed which means less expansion cooling of the gas.